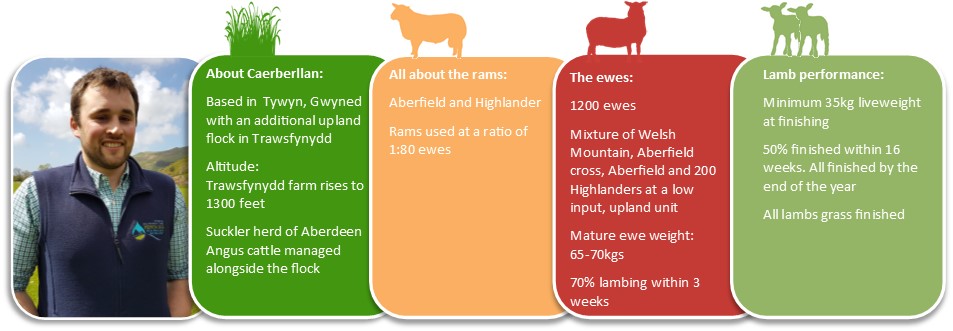

Dafydd Jones, Caeberllan, Tywyn

Introducing one simple, yet significant change to a low input sheep enterprise, is enhancing its sustainability, says Dafydd Jones. “Six years ago, we invested in an Aberfield ram to start grading up a pure Welsh Mountain flock resulting in a 28% increase in output without any further inputs or increasing stocking rate.

“Being a low input system, not feeding sheep concentrates, we were cautious to say the least of changing to a very different type of ewe, but seeing market requirements, a better carcase lamb was needed, yet still producing a good ewe lamb replacement without incurring any extra input costs.”

It was the facts, the figures and the science behind the Innovis breeding programme which led the Jones to initially consider investing in Aberfield genetics. “Any available data a shepherd can use to drive a sheep enterprise forward has to be a plus, for us on a grass based system, it’s a win win,” he explains.

“We aim for a 35kg liveweight Aberfield cross finished lamb, many going away well over 40kg and the great thing is 50% of the crop is now reaching target finished weight by August at 16 weeks – that’s a huge advantage to us since it frees up more grazing for the sucklers. Nowadays, the entire lamb crop is cleared by the end of the year all on grass, and a single artic load of fodder beet amount to our only input cost during lambing to aid ewe energy levels. Previously we were just starting to draw finished lambs at 16 weeks, they’re now gone sooner and heavier.”

Earlier finishing also reduces other input costs, says Dafydd. “We’re minimising the number of doses, pour-ons so there’s fewer gathers and less labour required.”

He continues: “The entire flock is lambed outdoors, low intervention requirements are key, the Aberfield is proving to be a cracking mother whatever the weather. We put one ram to 80 ewes and 70% are lambing within the first three weeks, I never imagined an Aberfield ewe would be so easy to keep and rear a quality set of twins; kilos of lamb reared per ewe has significantly increased.”

Three hundred Aberfield ewe lambs are annually retained for replacements. This year the strongest were put to ram. “We felt since they’d developed and grown so much, it was a no brainer to try. It was the first time ever we’ve lambed lambs, and we’ll do it again; it will hugely reduce the cost that comes with breeding replacements on winter tack, these ewe lambs will be paying back a year sooner.”

The Jones family also farm a 200-ewe flock at Trawsfynydd, Gwynedd, where Highlander is used as the maternal sire.

“These ewes are managed on an extremely low input system on land rising to 1,300 feet; they’re lambed outdoors with minimal labour input, we simply let the ewes get on with it. The flock is only handled for marking lambs, shearing, weaning and tupping.

“We chose the Highlander from the basis of needing a hardy animal, to survive in the prolonged cold and wet winter, but producing a lump of a lamb off poorer grazing grass. Their tight skins and good teeth ensure a robust ewe with longevity, and most importantly cheap labour and management requirement.”